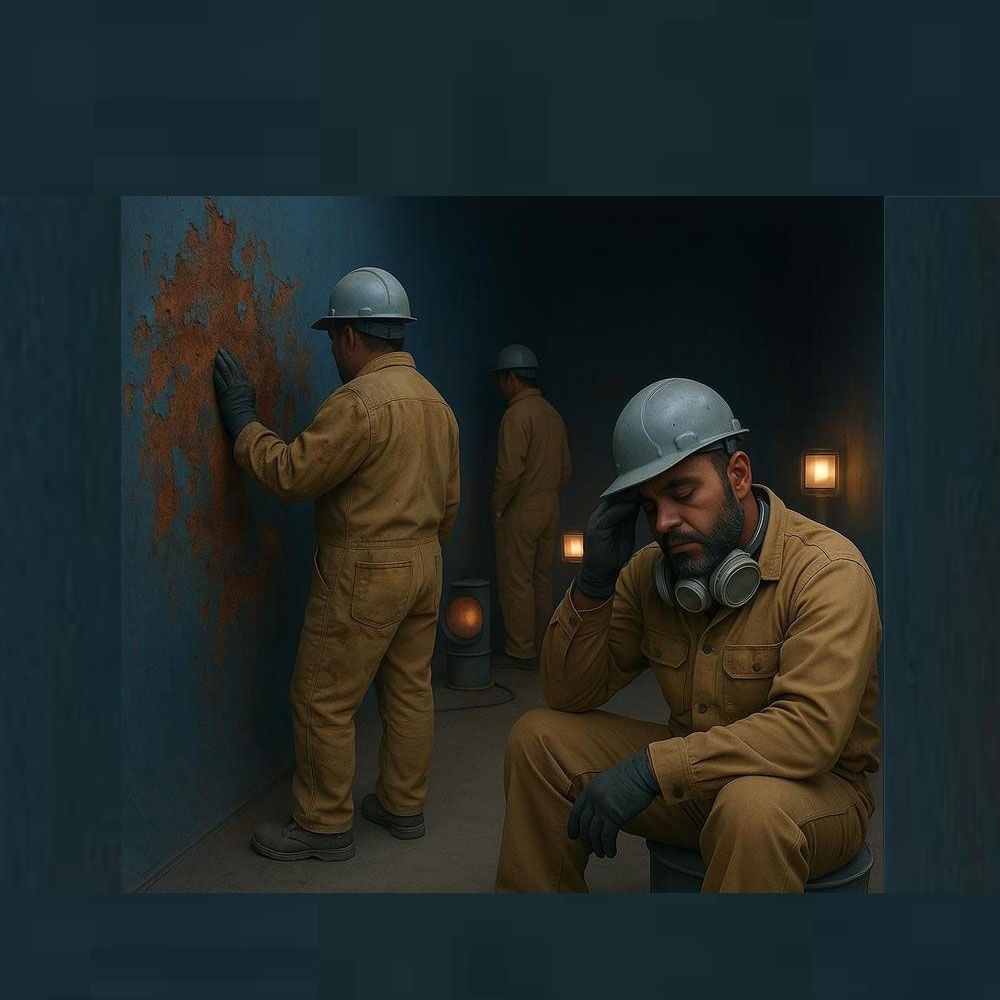

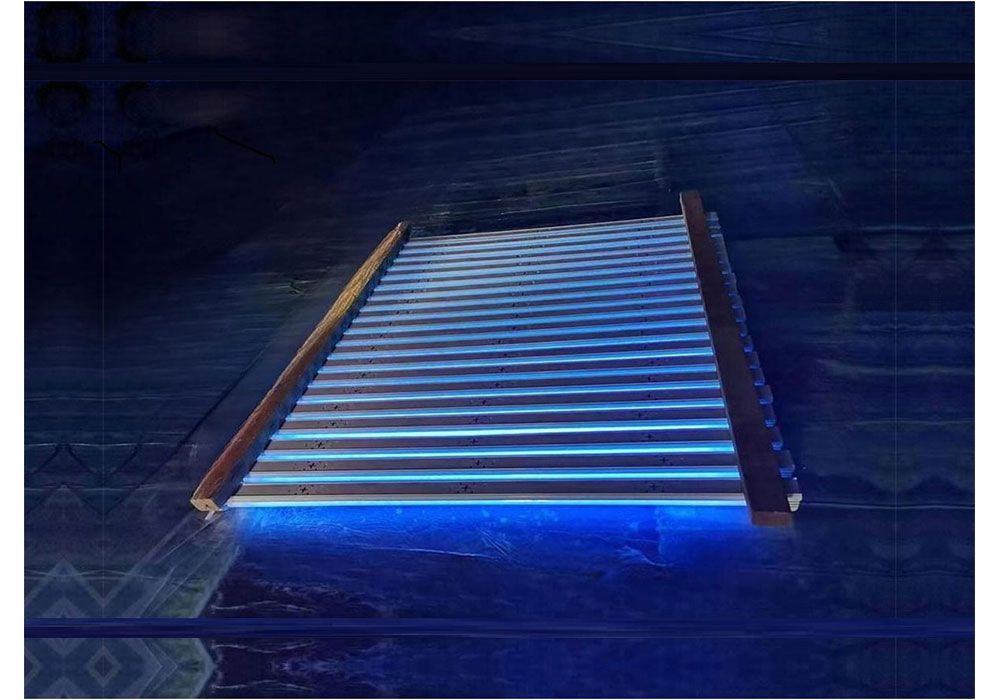

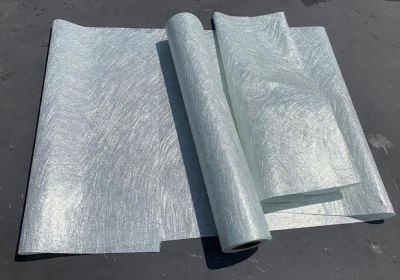

At Hangzhou Sanfreund Technology Co., Ltd., we’re pushing the boundaries of corrosion protection with over 20 years of global expertise and Japanese innovation. Specializing in UV-curable FRP (Fiber-Reinforced Polymer) coatings, we deliver fast, seamless, and highly durable protection against corrosion, leaks, and chemical damage. Our cutting-edge technology ensures unmatched curing speed, environmental safety, and reliability. Serving industries such as petrochemical, marine, crude oil, wastewater treatment, and more, Sanfreund delivers innovative, reliable, and high-performance coating solutions trusted by industry leaders worldwide.