Our pipeline coating service uses the pig lining method to revive and protect old or deteriorated pipelines without the need for complete replacement. This efficient, internal lining process is ideal for restoring crude oil pipelines, water lines, and other industrial systems—improving performance, extending lifespan, and reducing maintenance needs.

Why Pig Lining?

Long-Lasting Protection: A high-performance internal coating made from vinyl ester resin with glass flakes provides superior resistance to corrosion, abrasion, and chemical exposure—lasting for decades.

Minimal Disruption: The process is completed on-site using specialized pigs, reducing the need for excavation or downtime.

Restored Flow Efficiency: The smooth coated surface eliminates rust and reduces scale buildup, maintaining consistent flow rates over time.

Cost-Effective Alternative: Pig lining is significantly faster and less expensive than full pipe replacement.

How the Process Works

1. Pipeline Sectioning

The pipeline is divided into sections of up to 2,000 meters to allow for controlled application.

2. Preparation

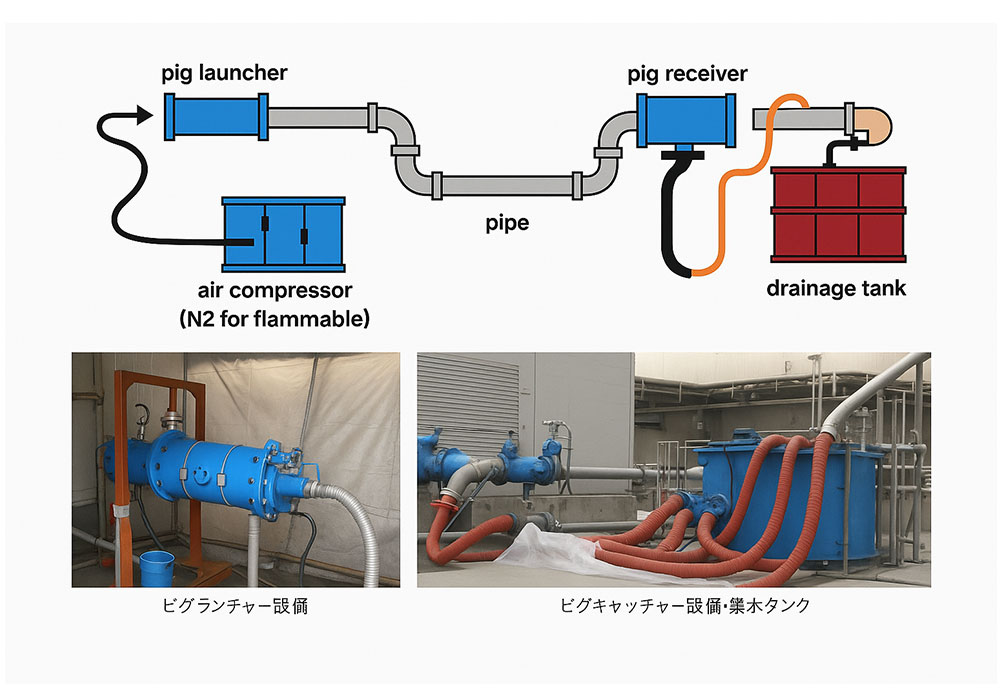

Valves and in-line equipment are temporarily removed and replaced with straight pipe. Pig launchers and receivers are installed.

3. Equipment Setup

Assemble pig launcher, pig receiver, and other equipment as below. If flammable gas remains inside

of pipe, use nitrogen gas instead of air

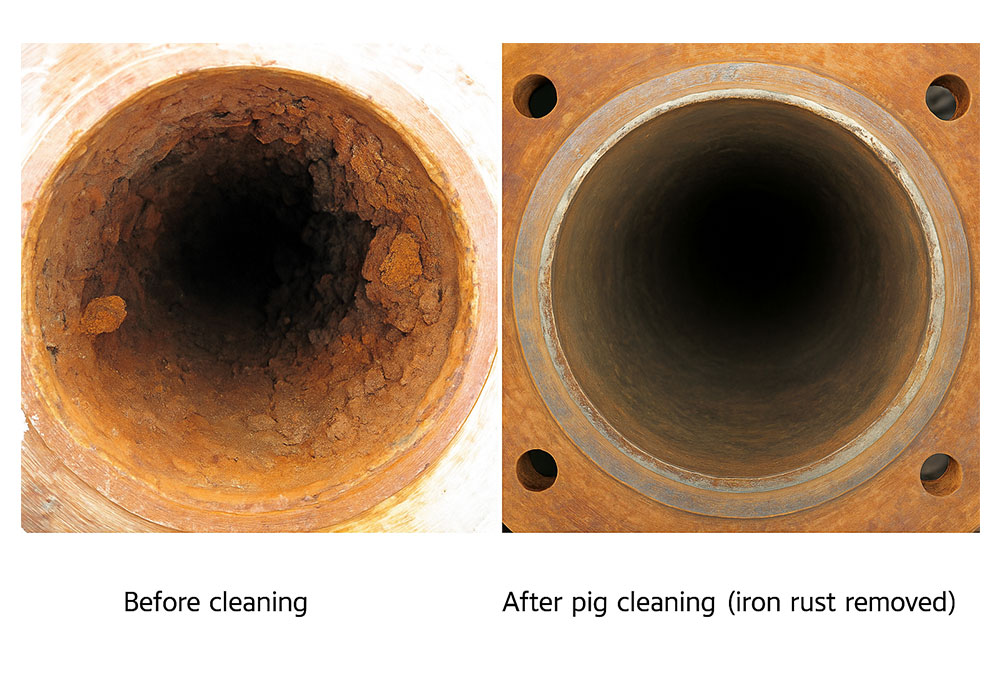

4. Cleaning

Cleaning pigs remove rust, scale, and debri inside the pipe, preparing the surface for coating.

5. Drying

The interior is dried thoroughly using air or nitrogen to ensure proper adhesion of the lining.

6. Lining Application

A primer and two coats of vinyl ester resin with flakes are applied internally using specially designed pigs, forming a tough, corrosion-resistant layer.

7. Inspection and Restoration

After lining, the interior is inspected with an endoscope and coating thickness is verified. Original components are reinstalled.