- Home

- FRP Coating

UV-Curable FRP Coating

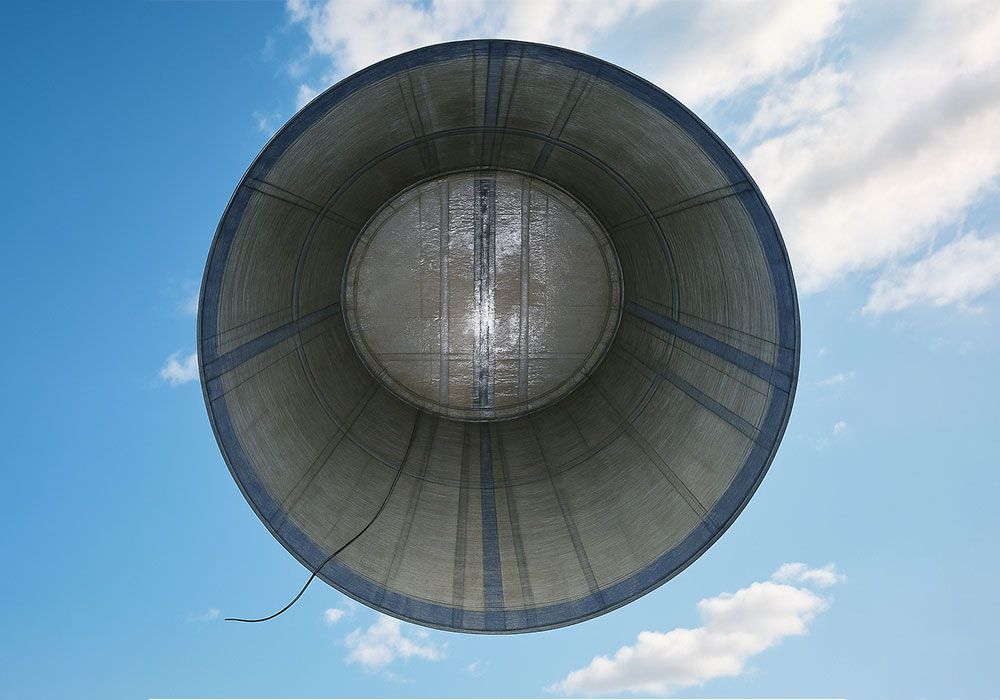

Looking for a reliable solution to protect your assets from corrosion and leaks? Our UV-Curable FRP (Fiber-Reinforced Polymer) Coating from Hangzhou Sanfreund Technology Co., Ltd. offer just that. Whether you're in the marine, petrochemical, crude oil, or wastewater treatment industries, it delivers excellent adhesion, outstanding chemical resistance, and long- lasting durability. It’s the trusted choice to keep your equipment and surfaces performing at their best, even in the harshest conditions.

We are committed to delivering exceptional quality and focusing on every detail to ensure the best experience for our customers.

Product Features

-

UV-Curable: Cures in just 20–30 minutes with UV light — no heat needed. Perfect for fast installs, even in cold conditions. - Leakage Prevention: Creates a seamless, impermeable seal that eliminates seepage and guards against environmental hazards.

- Enhanced Adhesion: Formulated with epoxy resin for superior bonding strength, surpassing traditional coatings in adhesion and resilience.

- Temperature Tolerance: Effective in environments below 100°C ~ -20C maintaining integrity under high-temperature conditions.

- Fast, Easy Installation: Quick and easy application process with no curing time. Multiple tanks (e.g., two 10 KL) can be lined in just 5–10 days, minimizing downtime and reducing labor costs.

- Static Conductive Layer: Integrated static conductive properties reduce static accumulation, enhancing safety in flammable environments.

- Durability: Formulated for extreme petrochemical exposure — extends tank life beyond 15 years with zero compromise.

- Chemical Resistance: Tested and proven to resist crude oil, gasoline, and 14+ industrial chemicals — built for the toughest environments.

- Flexible Thickness: Available in a standard 2mm thickness, with the option to add additional layers post-curing for enhanced protection in extreme conditions.

- Mechanical Integrity: Retains structural integrity under stress from temperature fluctuations and chemical exposure.

- Uniform Thickness: Consistently manufactured to prevent pinholes, sagging, or drooping, ensuring uniform application quality.

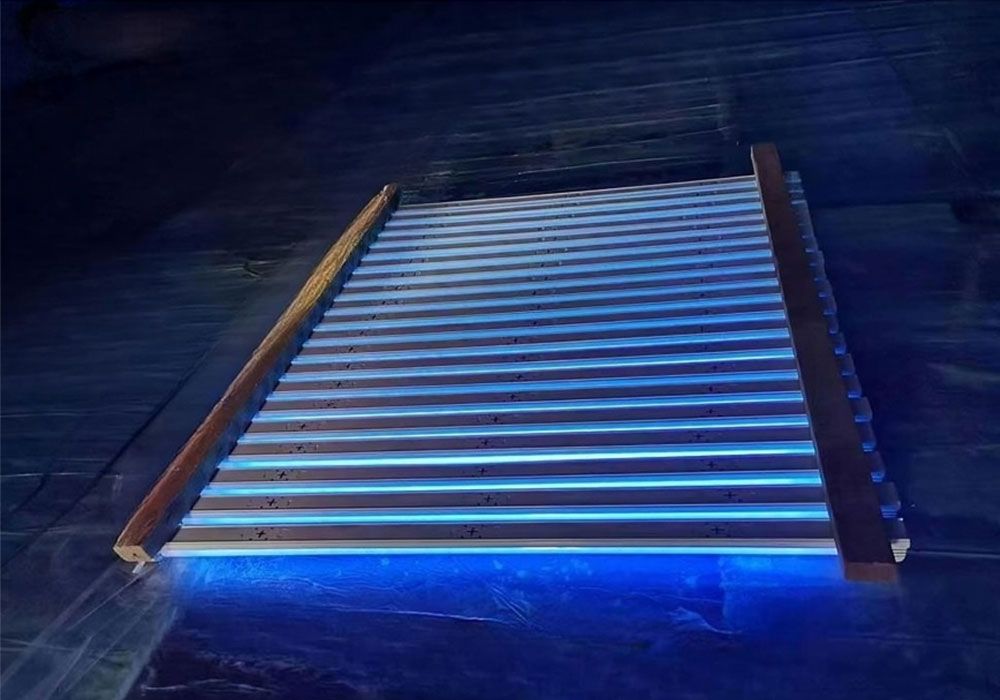

- Leak Detection System: This setup allows for the integration of a leak detection system in the interstitial space of SF double-shell underground tanks, enhancing safety and enabling early detection of leaks. The FRP layer provides grounding, supporting continuous monitoring of potential leaks by forming a 3D cloth structure on the lining inside the tank.

Distinctive Feature: UV-Curable Technology

What makes our FRP Coating truly stand out is its game-changing UV-curable technology. Instead of relying on heat or waiting hours for it to dry, this smart coating fully cures in just 20–30 minutes with the power of UV light. That means faster installations, less downtime, and no worries about cold weather slowing things down. It forms a strong, even bond every time—cutting energy use and delivering reliable protection you can count on. Whether you're working in tough conditions or tight schedules, this coating keeps things moving and your equipment protected.

Distinctive Feature: Built-In Leak Detection System

Safety meets innovation with our optional leak detection system—designed to give you peace of mind when it matters most. This smart feature is built right into the coating’s structure, using a 3D cloth layer and embedded sensors to actively monitor for leaks in real time. Whether your tanks are underground or suspended, this system helps you catch issues early, respond quickly, and avoid costly environmental damage. It’s easy to install, seamlessly integrated, and ideal for industries where safety and compliance are non-negotiable. With this advanced layer of protection, you’re not just coating your tanks—you’re future-proofing them.

Comparison with Traditional Method

Feature | FRP Coating | Traditional Spray Coatings |

foaming | Vacuum stirring and complete defoaming during production | Artificial defoaming often remains incomplete. |

Adhesive Properties | Contains epoxy resin with strong adhesion | Uses unsaturated polyester with lower adhesion |

Corrosion Resistance Performance | Superior corrosion resistance due to epoxy resin | Lower corrosion resistance due to high ester bond content |

Curing Performance | Pre-mixed agent enables uniform, traceable light curing. | Heat curing is manual, inconsistent, and lacks traceability. |

Environmental Protection and Safety | No toxicity, no flammable gas, safe for personnel. | Emits toxic, flammable gases—explosion and health risk. |

Material Modulation | Uniform thickness, unaffected by climate and environment | Proportional mixing based on environment, quality varies |

Welding Line and Seam Treatment | Soft coating covers seams easily and uniformly | Multiple spray cures, uneven quality |

Construction Remediation | Easy to repair post-construction defects | Difficult to repair, uniform quality hard to achieve |

Coating Quality | Ensures uniform, defect-free coating. | Prone to unevenness, defects, and contamination. |